Multi Cavity Design Silicone Rubber Molding Soft Injection Moulding

Silicone Rubber Molding Features:

1. Almost nil shrinkage, cure at room temperature

2. High Shore A hardness (approx.40)

3. Good transparency, high tear strength

4. Food grade silicone (environmental, odorless and nontoxic)

5. High resistance to high temperature and aging(resist -60 to

250℃)

6. High chemical resistance to aggressive components of some types

of resins

7. Outstanding resistance to common casting resins

Silicone Rubber Molding is a process used to produce pliable,

durable parts in high volumes. During the process, several

components are necessary: an injector, a metering unit, a supply

drum, a mixer, a nozzle, and a mold clamp, among others.

Silicone Rubber Molding is a common technology used for the

production of different products for medical and electrical

applications, among others. In addition to the innate properties of

the material, the parameters of the process are critical too. LSR

injection molding is a multistep process that is presented in

Figure 1.

The first step is the preparation of the mixture. LSR usually

consists of two components, pigment, and additives (fillers for

example), depending on the desired properties of the final product.

In this step, the ingredients of the mixture are homogenized and

can be combined with the temperature stabilization system for a

better control of silicone temperature (ambient temperature or

silicone preheating).

The internal part of the Silicone Rubber Molding, called inserts,

which are embedded in the silicone coating after the injection

process, are placed in the mold. These inserts can be kept in

ambient conditions prior to injection or preheating.

Silicone Rubber Molding are normally supplied in barrels. Because

of their low viscosity, the material can be pumped through

pipelines and tubes to vulcanization equipment.

Our Advantages:

1. Professional experienced manufacturer for many years

2. Competitive price from factory

3. Timely and short lead time

4. OEM & ODM are welcome

FAQ:

1. When can I get the price?

A: We usually quote within 24 hours after we get your inquiry.

2. How long is the lead time for mold?

A: It depends on the mold’s size and complexity. Normally, it nees

about 25-35 days.

3. I don't have 3D drawing, how should I start the new project?

A: You can provide us a sample, we will make 3D drawing design.

4. Can we mass produce in your local?

A: Yes, you can leave the mould in our factory, we can produce for

you.

5. Can we get a sample when mould finished?

A: Yes, we usually send out samples for customers' checking, then

mass production after samples comfirmed.

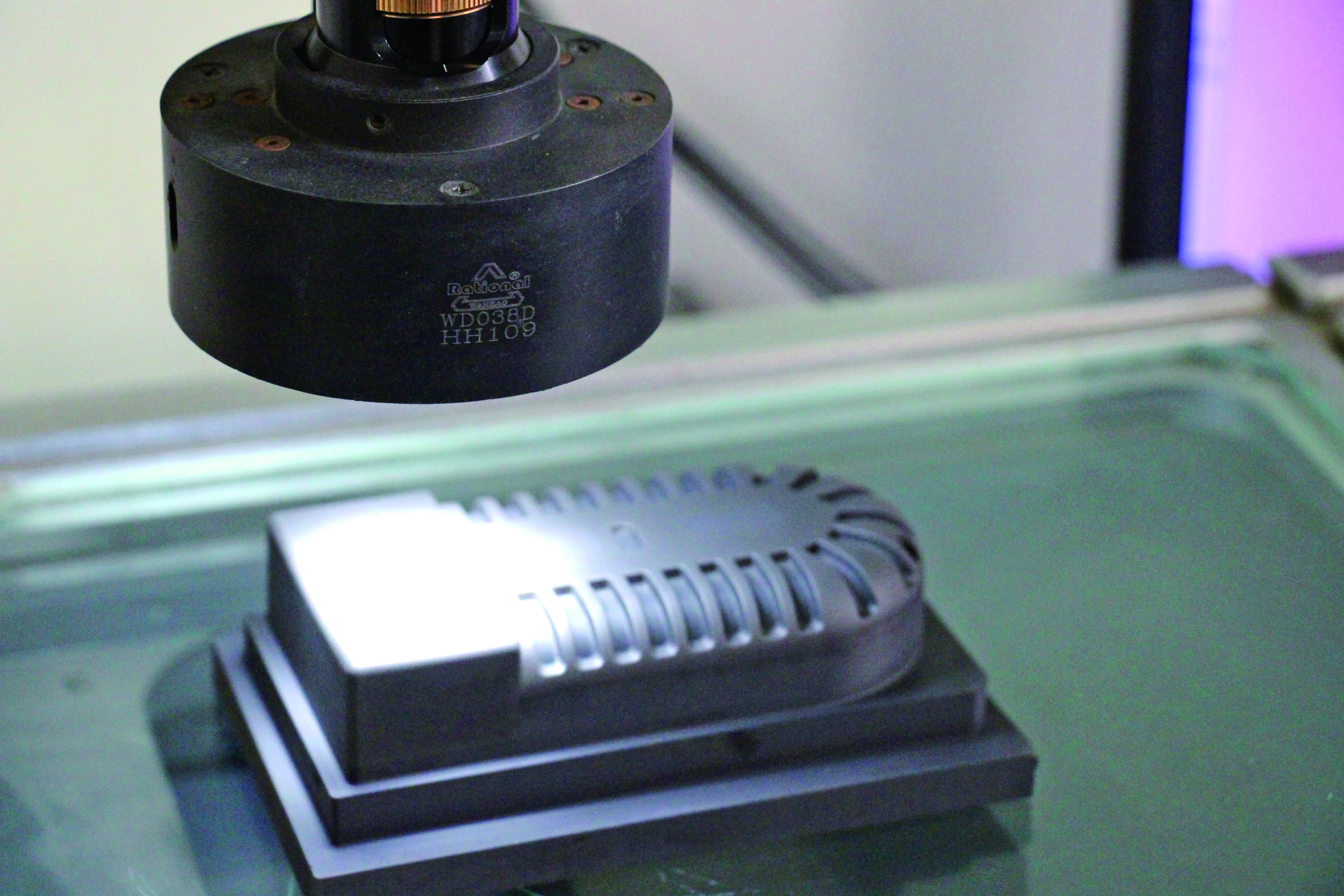

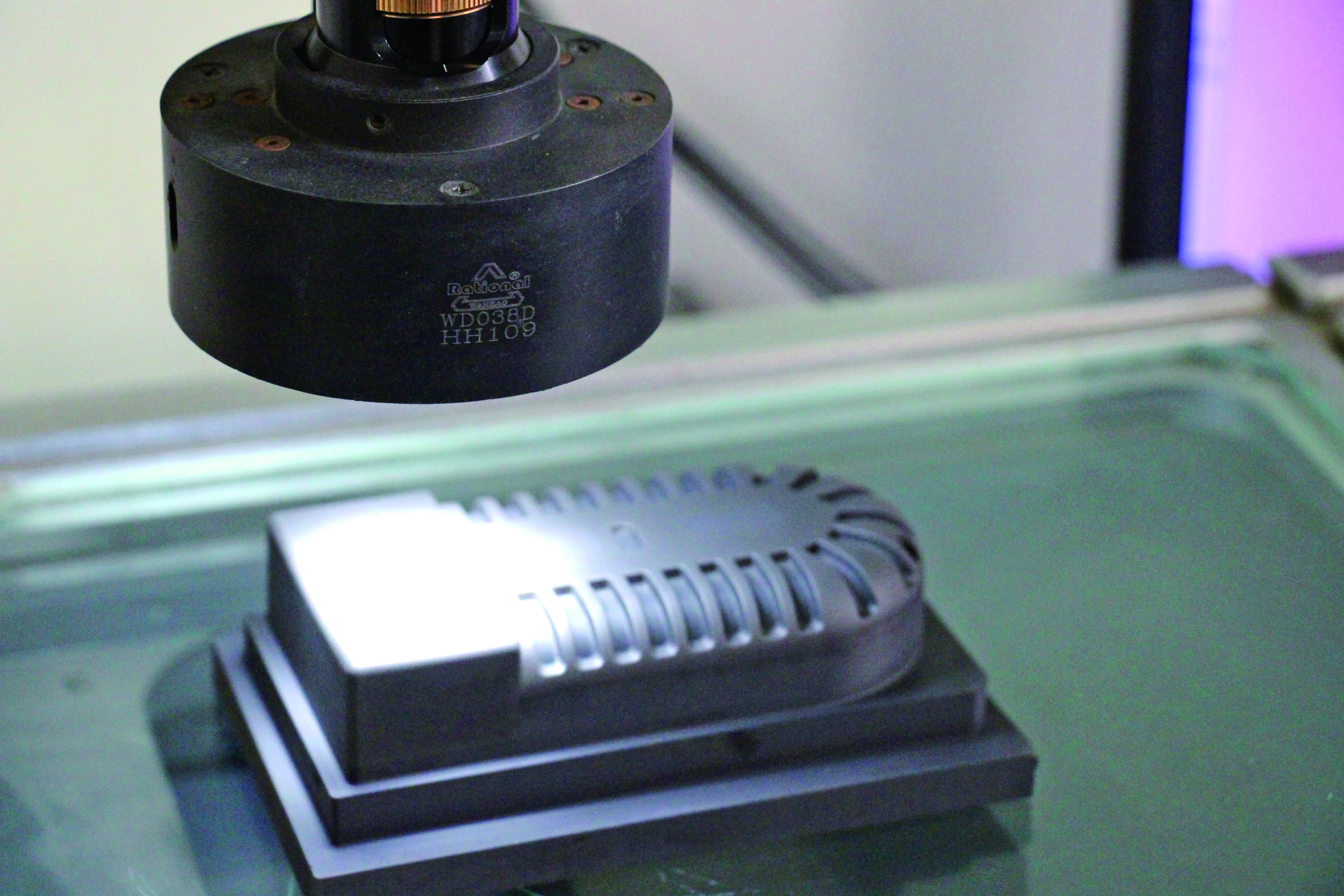

6. Before shipment, how to make sure the products quality?

1) We have QC to inspect the products before each shipment.

2) We can send you videos to show the production process.

3) You can come to visit our factory or ask a third party for

inspection.

7. How could I pay?

A: Paypal, Western Union, T/T are acceptable, so just let us know

which is convenient for you.

8. How to ship?

A: By sea/ By air/ By Express.