Company Profile

We have plastic injection mould and plastic products factories: Jinjiang LiQi Mould Co., Ltd & Quanzhou Liqi

Plastic Products Co., Ltd to supply the one-stop service of

mold development-mold production-injection molding - pad printing,

oil injection - flow assembly - product packaging.

Address:Anping Industrial Area Anhai town Jinjiang,Quanzhou,Fujian

Sales Office registed: Quanzhou Luckyseven Import &Export Trading Co.,Ltd.(In charge

of Sales, Design,Shipping ,Payment, attending trade fair)

Product Range: Plastic Toys, Baby Toys, Promotion Gadgets, Stationery Sets,

Plastic Products, Moulds.

All Products conform to: EUROPEAN AND AMERICAN SAFETY STANDARD likes EN71,REACH,ASTM etc.

Key Customers including: Disney, Egmont ,Panini, BBC, Bumbo International, T-Rex Flunch,

Quick,Hasbro, Mattel, HelloKitty,Premium World etc.

Factory area:

Mould workshop: abt 1500 squre meters

Toy factory1: about 2200 squre meters

Toy factory2: about 6000 squre meters

Number of Building: 5

Number of workers in mould factory: 40 workers

Number of workers in toys production line:80-120 workers

Factory established: in 2003

Turnover:5000,000-9000,000US$

Latest Social audit in Jun 2018- 2019 : SMETA PILLAR 4,Disney ,NBCU

Information Of Factory

Founded in 2003, Jinjiang Liqi mould Co., Ltd. is located in Anping

Development Zone, Anhai Town, Jinjiang, an important industrial

town of Quanzhou. It is 6km away from the expressway intersection.

It is less than an hour's drive from Quanzhou airport and Xiamen

airport, and less than 20 minutes' drive from Jinjiang motor car

station. The transportation is very convenient. Our company is

mainly composed of two factory areas: mold manufacturing and

injection molding production. It is mainly engaged in the

customization of injection mold, the production of plastic products

and the processing and assembly of finished products. Our company

has advanced mold and injection molding equipment, perfect

scientific management system, regular safety equipment and stable

operating technicians. Have the one- stop service of mold

development - mold production - injection molding - pad printing,

oil injection - flow assembly - finished product packaging.Since

its establishment in 2003, mold manufacturing has always been

committed to producing and developing high-quality injection molds.

Pay attention to every detail of the mold, and strive to pursue

customer satisfaction from the standpoint of customers. Jinjiang

LiQi Mould Co., Ltd. was officially registered in 2010. Based on

the principle of being responsible for the design and production of

each step, we are stabilizing and improving the scale of the

company step by step. Our core business strategy is to provide one-

stop mold solutions, including mold component structure design,

mold design and mold making. At present, 70% of injection molds are

exported to Europe, Africa, Italy, Spain, South Africa, Southeast

Asia and other countries.

Detail determines quality

It's not easy to do every simple thing well. It's extraordinary

to do every ordinary thing well.

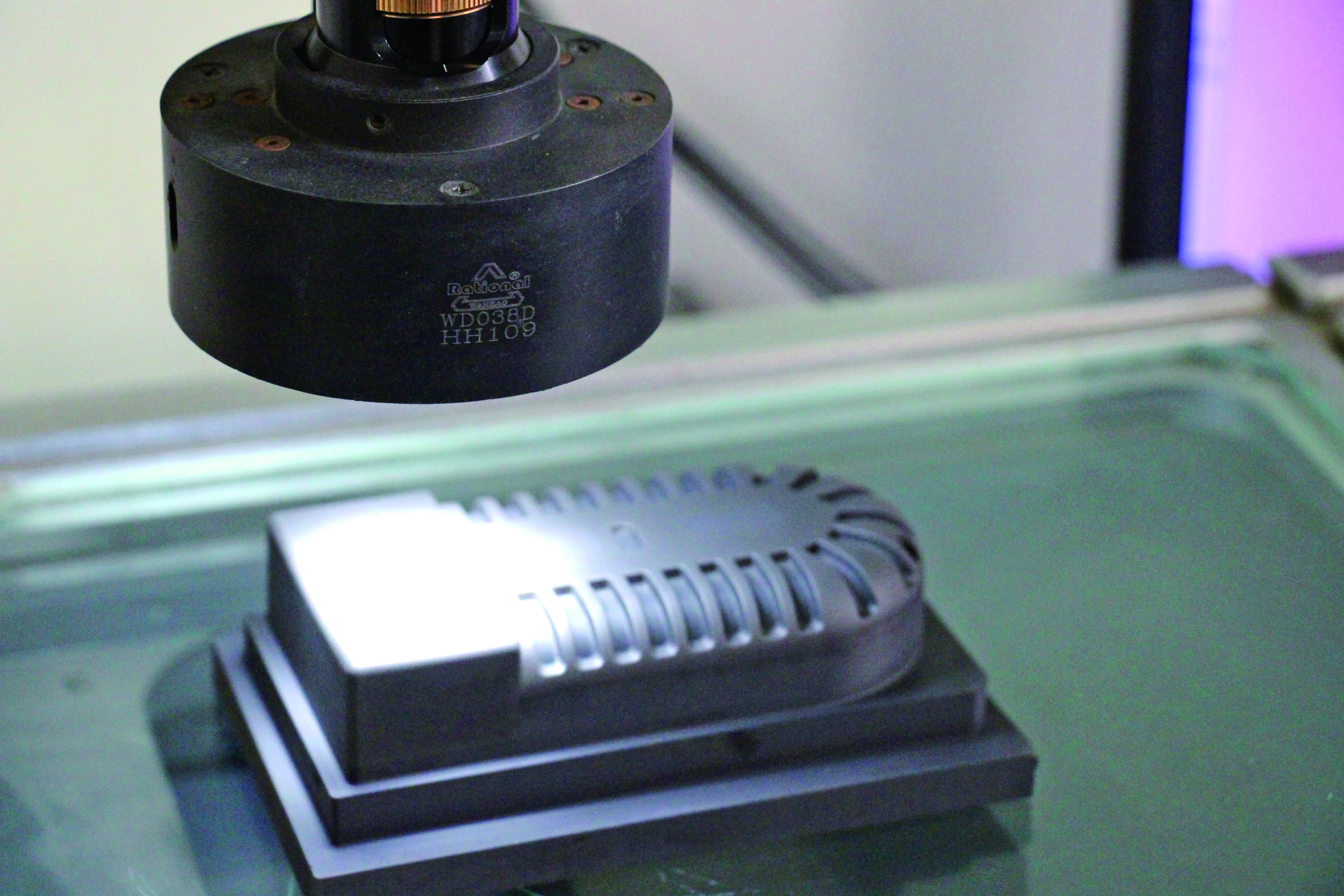

Professional Plastic Injection Mould Workshop:

Professional Machine do the professional mould:

Mold Design and Manufacturing Process: