Silicone Products Plastic Polypropylene Injection Molding Rapid

Tooling

Specification:

Polypropylene is a polymer formed by addition polymerization of

propylene. It is a white waxy material with a transparent and light

appearance. The chemical formula is (C3H6)n, the density is

0.89~0.91g/cm3, It is flammable, with a melting point of 189℃,

softening at about 155℃, and the use temperature range is -30~140℃

. It is resistant to corrosion by acids, alkalis, salt solutions

and a variety of organic solvents below 80°C, and can be decomposed

under high temperature and oxidation. Polypropylene is widely used

in the production of clothing, blankets and other fiber products,

medical equipment, automobiles, bicycles, parts, pipelines,

chemical containers, etc. It is also used in food and

pharmaceutical packaging.

Polypropylene Injection Molding is a commonly used plastic

injection molding material with three main ingredients:

acrylonitrile, butadiene, and styrene. Each of these monomers

imparts specific properties and provides Polypropylene Injection

Molding terpolymer with a robust combination of features.

Advantages:

Polypropylene is a polymer formed by addition polymerization of

propylene. It is a white waxy material with a transparent and light

appearance. The chemical formula is (C3H6)n, the density is

0.89~0.91g/cm3, It is flammable, with a melting point of 189℃,

softening at about 155℃, and the use temperature range is -30~140℃

. It is resistant to corrosion by acids, alkalis, salt solutions

and a variety of organic solvents below 80°C, and can be decomposed

under high temperature and oxidation. Polypropylene is widely used

in the production of clothing, blankets and other fiber products,

medical equipment, automobiles, bicycles, parts, pipelines,

chemical containers, etc. It is also used in food and

pharmaceutical packaging.

Applications:

1. Machinery and automobile manufacturing parts

2. Electronic and electrical industrial devices

3. Construction industry

4. Agriculture, fishery and food industry

5. Textile and printing industry

6. Other industries

Our Advantages:

1. Professional experienced manufacturer for many years

2. Competitive price from factory

3. Timely and short lead time

4. OEM & ODM are welcome

FAQ:

1. When can I get the price?

A: We usually quote within 24 hours after we get your inquiry.

2. How long is the lead time for mold?

A: It depends on the mold’s size and complexity. Normally, it nees

about 25-35 days.

3. I don't have 3D drawing, how should I start the new project?

A: You can provide us a sample, we will make 3D drawing design.

4. Can we mass produce in your local?

A: Yes, you can leave the mould in our factory, we can produce for

you.

5. Can we get a sample when mould finished?

A: Yes, we usually send out samples for customers' checking, then

mass production after samples comfirmed.

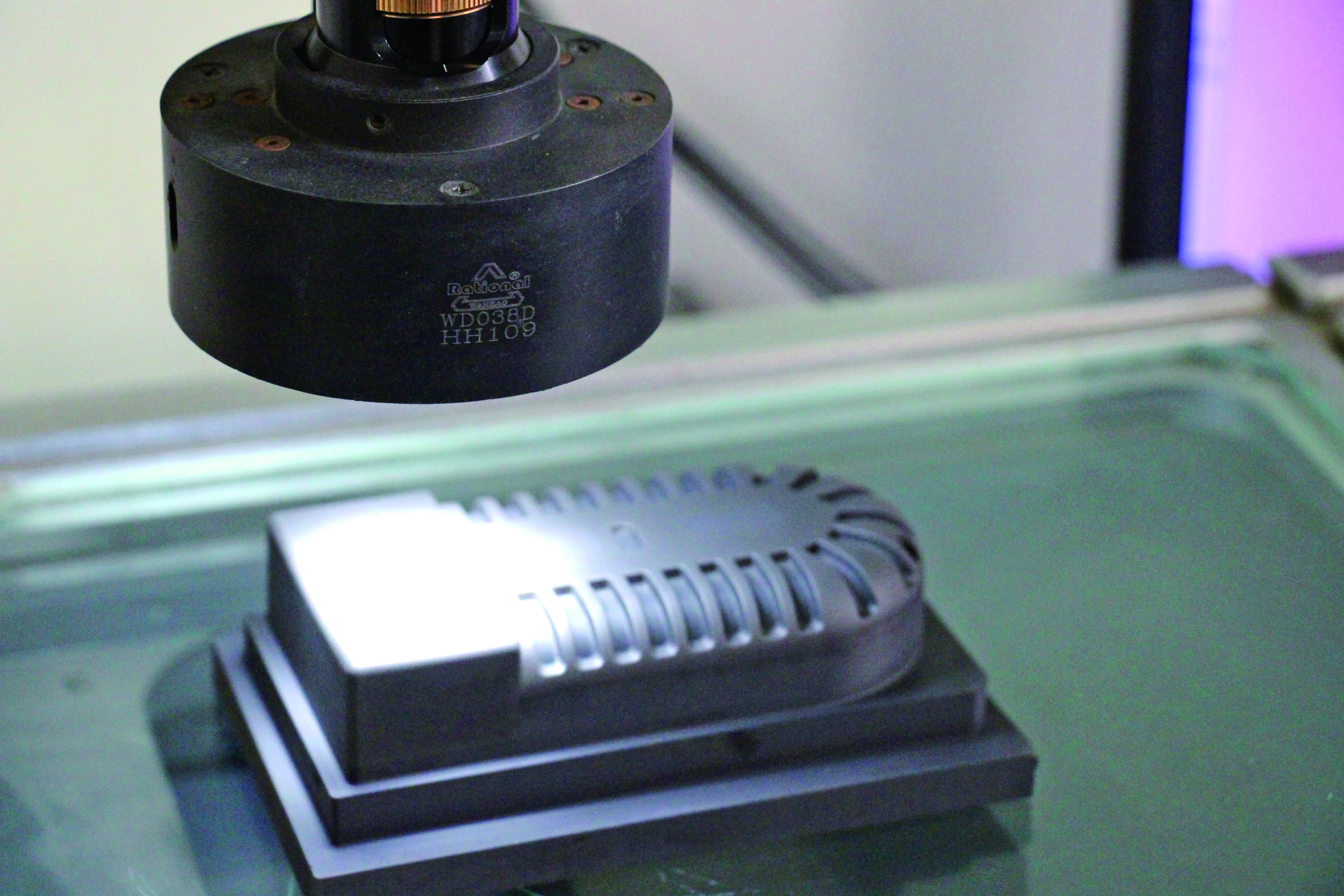

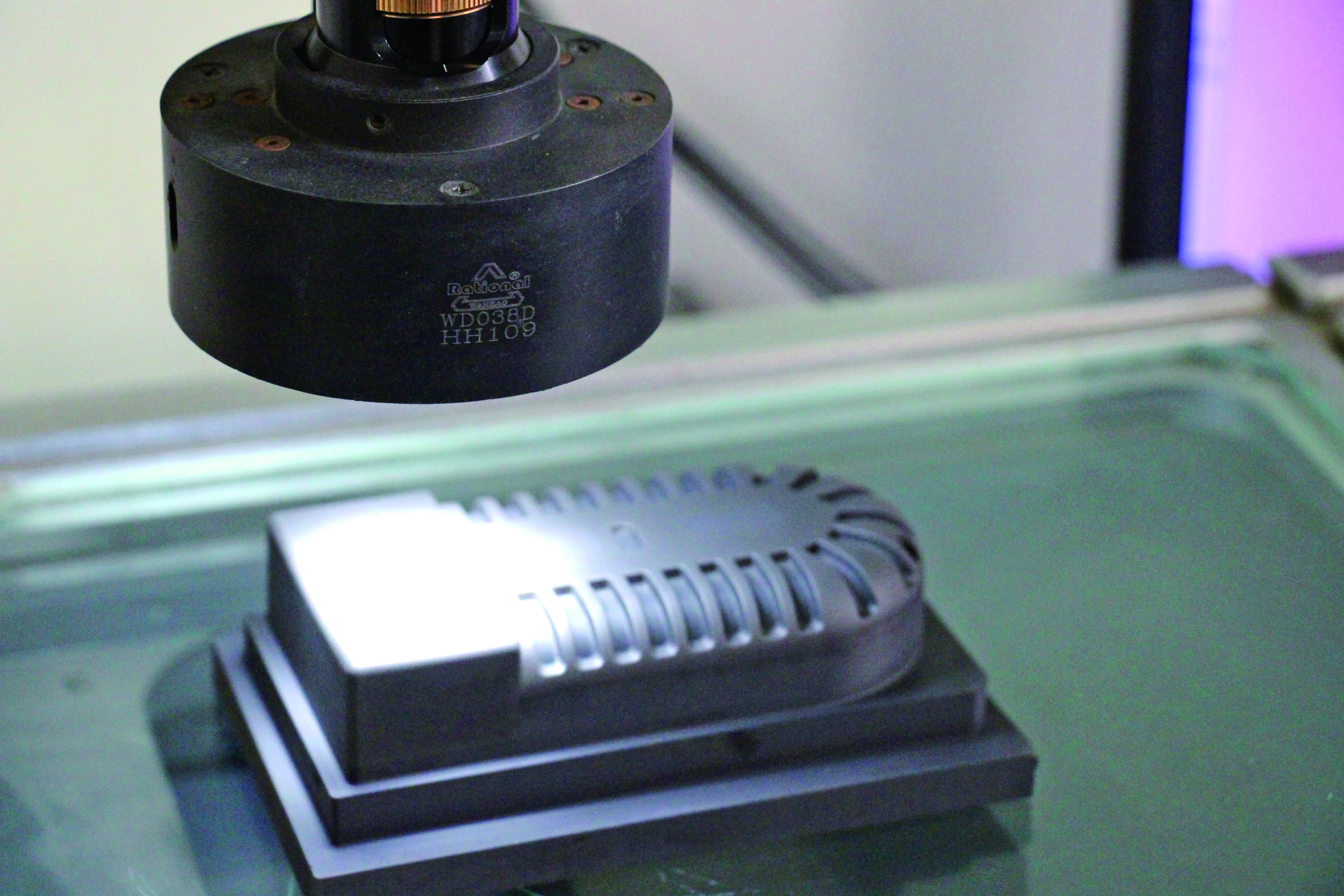

6. Before shipment, how to make sure the products quality?

1) We have QC to inspect the products before each shipment.

2) We can send you videos to show the production process.

3) You can come to visit our factory or ask a third party for

inspection.

7. How could I pay?

A: Paypal, Western Union, T/T are acceptable, so just let us know

which is convenient for you.

8. How to ship?

A: By sea/ By air/ By Express.