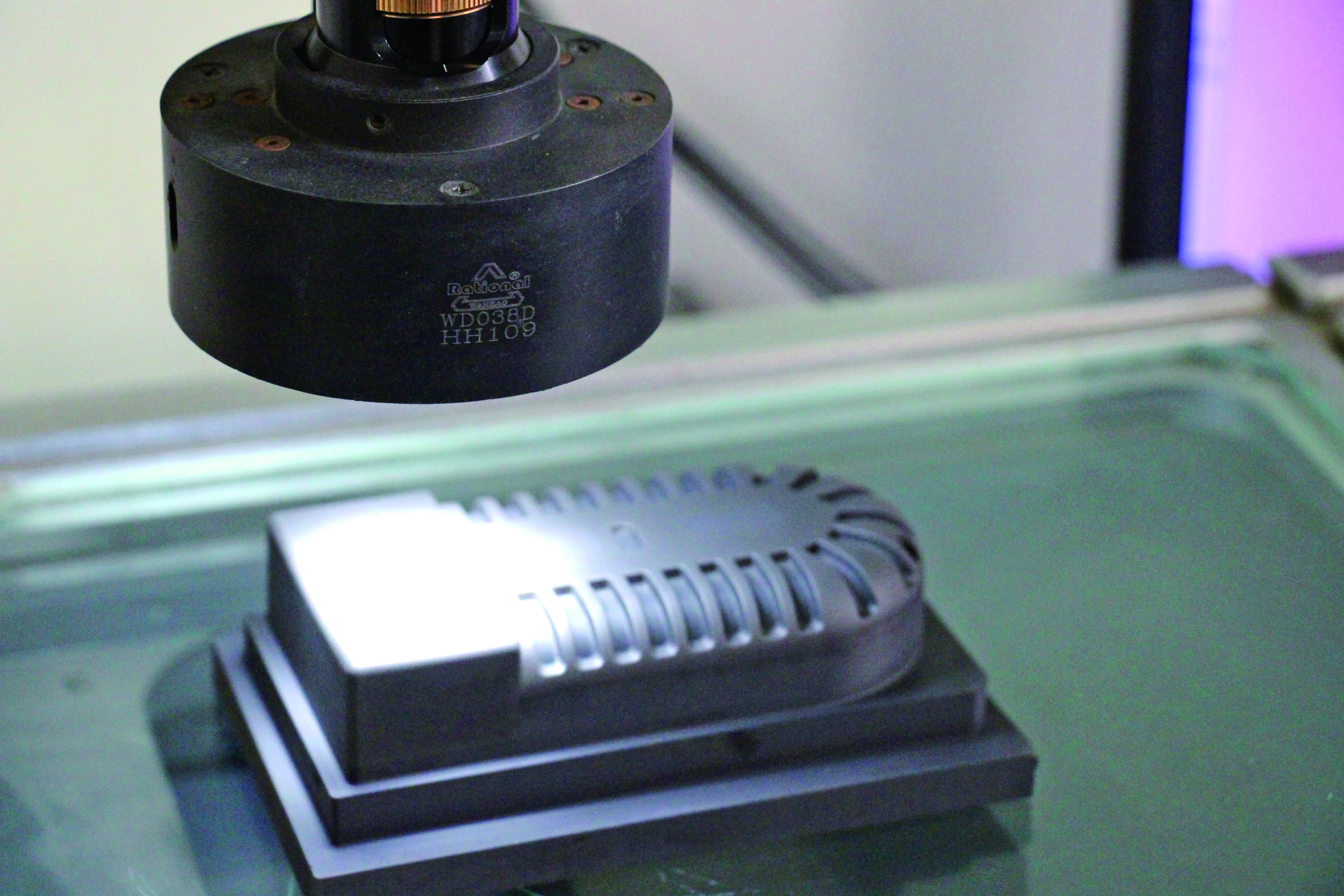

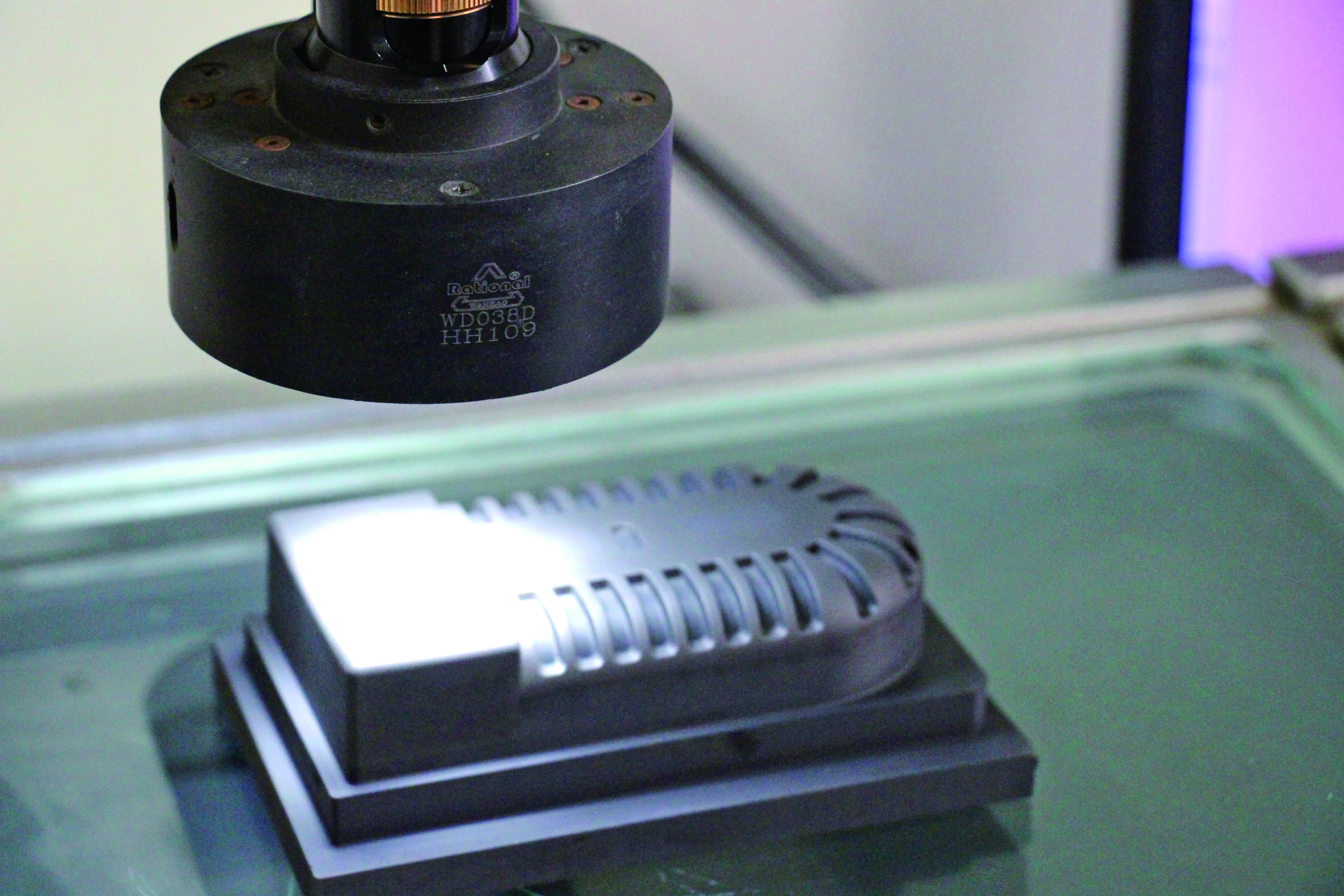

Double Color Silicone Rubber Molding Gate Side Machine

Liquid injection molding is an industrial fabrication method that

molds stock materials into a range of components and products. It

differs from the standard reaction injection molding process in

that it relies on mechanical mixing rather than pressurized

impingement mixing, and it focuses specifically on liquid silicone

rubber and similar elastomeric materials. It is capable of

efficiently producing a large number of versatile items, including

seals, o-rings, isolators, and electronic contacts.

| Product Name | High Precision Liquid Silicone Injection Molding |

| Material | Stainless steel P20/718/738/NAK80/S136 |

| Mold Type | Single or multicolor/Overmold/one male die&two female

die/customization |

| Design & Size | Customize |

| Mold Trial | Available |

| Surface Finishing | MT standard, high gloss polishing |

| Application | Baby products/Medical supplies/Car Accessories/Connector

seals/O-ring/Intelligent wearable products/Optical product/Kitchen

ware/Sanitary ware |

Product Description:

1. We have 6 CNC machines, 3EDM machines, we can make over 50sets

rubber molds per month.

2. Compression/transfer/injection (both hot runner and cold runner

are available) types.

3. The common mold steel we use are NAK80, P20, 4140, S50C

4. We have 10years experience in making rubber moulds, especially

for rubber molds of electronic rubber parts, automotive rubber

parts, toy tires, we are a leading rubber mould maker in China.

5. We have our own rubber products workshop, we can test the mold

before ship the mold to customer.

6. We are currently making molds for Japan, Italy, UK, USA, Canada,

South Asia companies.

7. Experience sales representative discuss with customer about the

mold design prior to mold making.

8. Lead-time, prototype mold in 3-7days, production mold in

1-2weeks, complicated rubber molds like cold runner injection

rubber molds in 30days

Application:

Molding silicone is suitable for reproducing and replicating

variety of products in large quantity, such us art crafts,

furniture, prototyping, architectural elements, garden ornaments,

shoe, tire, soap, candle, jewelry, vacuum bag and so on.

Our Advantages:

1. Professional experienced manufacturer for many years

2. Competitive price from factory

3. Timely and short lead time

4. OEM & ODM are welcome

FAQ:

1. When can I get the price?

A: We usually quote within 24 hours after we get your inquiry.

2. How long is the lead time for mold?

A: It depends on the mold’s size and complexity. Normally, it nees

about 25-35 days.

3. I don't have 3D drawing, how should I start the new project?

A: You can provide us a sample, we will make 3D drawing design.

4. Can we mass produce in your local?

A: Yes, you can leave the mould in our factory, we can produce for

you.

5. Can we get a sample when mould finished?

A: Yes, we usually send out samples for customers' checking, then

mass production after samples comfirmed.

6. Before shipment, how to make sure the products quality?

1) We have QC to inspect the products before each shipment.

2) We can send you videos to show the production process.

3) You can come to visit our factory or ask a third party for

inspection.

7. How could I pay?

A: Paypal, Western Union, T/T are acceptable, so just let us know

which is convenient for you.

8. How to ship?

A: By sea/ By air/ By Express.